Protect your hands with the highest quality leather MIG welding gloves!

During MIG welding, sparks and/or glowing weld spatter can be emitted. For this reason, it is important to properly protect your hands and forearms with heat resistant gloves. MIG/MAG welding is a versatile welding technique used in many industries such as boiler construction, shipbuilding, offshore, and the automotive industry. Weldas, as a specialist in welding protection, offers various solutions for welders with a wide range of A-quality leather MIG welding gloves.

What is the difference between MIG/MAG welding?

MIG welding and MAG welding are both a form of arc welding where the welding wire is fed continuously. It is a welding technique that allows it to work quickly and also achieve high-quality results. MIG and MAG welding are therefore widely used in places where high productivity is desired. The only difference between the welding techniques is the type of shielding gas used. Metal Inert Gas (MIG) welding uses an inert gas such as argon as a base, while Metal Active Gas (MAG) welding uses gasses like CO2 for example.

Characteristics of MIG welding gloves

Personal protective equipment (PPE) is very important during MIG/MAG welding. A good leather welding glove meets several criteria, including safety, comfort, ease of use and health. A cotton-lined welding glove provides protection against the heat generated during MIG welding, as well as against fire and molten metal spatter.

In addition, comfort and ease of use are important. Not only does the lining play a role, but also the fit, fingertip sensitivity, weight and abrasion resistance. The latter is determined by tensile strength, tear resistance, reinforced seams and stress points, as well as thread strength and flame resistance.

Finished with welting

The finish of the lined leather gloves at Weldas is specific to the MIG/MAG welding technique. This so-called welting protects the thread with which the heat resistant glove is sewn from sparks generated during the welding process. Because of the welting, this thread is not visible and cannot burn through if a hot welding spark lands on it. All heat resistant gloves used for MIG welding are equipped with welting for the longest possible life. In addition, the welting is not so thick that the seams interfere with the use of the MIG glove. When the welting is applied, the lining is also sewn in place so that it stays securely in place when the welding glove is removed.

Super strong KEVLAR® thread

Some of the cotton-lined welding gloves are sewn with DuPont KEVLAR® thread. KEVLAR® thread is a synthetic para-aramid fiber with a molecular structure that makes it incredibly strong. In addition, the ultra-strong thread is UV and abrasion resistant and can withstand extremely high temperatures up to 600 degrees Celsius. KEVLAR® thread is available in various grades from 1-ply to 5-ply. For Weldas gloves, both the top thread and the bottom thread are sewn with 3-ply KEVLAR®. DuPont and KEVLAR® are trademarks or registered trademarks of E.I. du Pont de Nemours and Company.

Quality leather welding gloves

At Weldas, we use quality split cowhide leather at every level. From the economically priced welding glove to the more luxurious ones, all our leather is of consistent and good quality. Of course, there may be defects, but because we tan Wet Blue leather in our own tannery in Cambodia, we can ensure consistent quality and maintain it. Our employees are trained to handle the leather as efficiently as possible, and extensive quality control is also carried out on the leather.

Types of MIG welding gloves

MIG gloves come in many varieties, not only in terms of design but also in size and color. Some welding gloves are not only available in standard sizes, such as L and XL, but also extra-large sizes up to XXXL and for smaller hands even size S. On the website, there is a size chart available for each product, indicating the circumference and minimum length for each size.

Straight and winged thumb

The MIG welding gloves with lining have either a straight or winged thumb. With a straight thumb the user can handle the MIG gun better. A winged thumb, on the other hand, allows the user to make a fist more easily. A straight thumb has a strap over the seams to protect it from heat and welding spatter. But this reinforcement also provides extra protection against cutting when working with sharp plates.

One finger model

In addition to models with separate fingers, a one finger model is available. This MIT welding glove is made in the traditional way. In the past, it was not so easy to make five fingers and a thumb. Moreover, there is less chance of holes due to fewer seams. However, the finger is necessary to operate the gun. This model of leather welding glove is mainly used by welders who have to weld many meters, for example in shipbuilding. This requires less finger sensitivity, but still good protection.

Left-handed welding gloves only

In addition, some glove models are also only available as left-handed pairs. Because the welder often feeds or assembles the welding gun with his left hand, this welding glove tends to get dirtier and wear out faster. The right hand usually lasts longer because it only holds the welding gun. By replacing only the left welding glove, costs are saved and the waste stream reduced (more sustainable for the environment).

Small order quantity

All MIG welding gloves are available in sets of 5 or in a box of 60 pairs, except for type 10-2112, which is only available in boxes of 60 pairs. Thanks to the large stock in our warehouse, we can deliver the MIG welding gloves quickly. From our warehouse in Bergen op Zoom, Weldas delivers throughout Europe.

You can determine which cotton lined welding glove is best suited for the welding task at hand by using the reference guide. This guide categorizes all welding gloves based on the type of work being performed, including the amount of amperage used.

Service

We manufacture all leather welding gloves ourselves and stand behind our product. Something can always go wrong, which is why we treat every complaint seriously. Of course, it is important that the correct glove is used for the intended application.

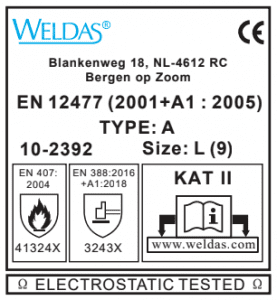

All Weldas welding gloves are labeled with a unique code. With this code we can trace the entire production process from the origin of the leather, to its tanning in the factory. In addition, each heat resistant glove has an information block printed on the cuff with the key information regarding the certification.

All Weldas welding gloves EN 12477 certified

Weldas considers the certification of the welding gloves very important and is also very strict about this. Chromium (VI) is used to process the leather of the welding glove, which is a carcinogenic substance for the skin. To ensure that the concentrations of these components fall within the legal standard of 3 mg per kg of leather, all Weldas welding gloves are EN 12477 certified. This is a European standard that combines three standards, EN 388, 407 and 420.

All cotton-lined MIG gloves fall into category A of this standard. This means that a hole appears only after 25 welding droplets in one spot. In addition, the abrasion resistance is very high at 500 cycles. The main difference between type A and B lies in the finger sensitivity of the glove. Type B gloves are more sensitive and usually not lined, while type A gloves are often lined welding gloves and have lower finger sensitivity. Cotton-lined gloves are recommended when high finger sensitivity is not required.

Other welding protection

In addition to the MIG welding gloves, you can also use a heat-reflective handshield on the heat resistant glove, to provide an even better protection against heat. In addition to protecting the hands, leather protection on the arms, abdomen, and thighs is advised when MIG welding; these are the so-called stress points when welding. Lava Brown™ welding clothing is made entirely of flame-retardant leather with double-stitched seams, electrically insulated buttons and additional leather patches at weak points. Another line is the Arc Knight® welding clothing. This welding garment has leather patches at stress points, but is otherwise made of cotton. This makes the welding clothing breathable, comfortable, and lightweight due to the combination with cotton. To prevent MIG welding spatters from reaching the neck or getting under the welding helmet, a flame-retardant helmet hood is recommended.

Questions about MIG welding gloves?

Do you have any questions about MIG/MAG welding gloves, product certifications or our other personal protective equipment for welding? Then, please contact us and we will be happy to assist you further.