Verschiedene Ledersorten und ihre Anwendung für die Herstellung der Kleidung und Handschuhe für Schweißer bei Weldas.

Weldas ist bekannt für seine Schweißbekleidung und Handschuhe aus hochwertigem Leder. Jede Art von Leder besitzt einzigartige Eigenschaften, die es für bestimmte Schweißaufgaben geeignet machen. Dieser Artikel untersucht die verschiedenen Lederarten sowie die Lederschichten und den Einfluss verschiedener Teile des Tierkörpers auf die Qualitätsstufe des Leders. Entdecken Sie von gespaltenem Rindsleder über Wildleder bis hin zu glattem Hirschleder, welche Art von Leder zu bestimmten Produkten aus dem Weldas-Sortiment passt.

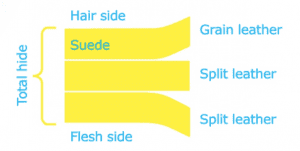

Terminologie der Lederschichten

Leder besteht aus mehreren Schichten. Die Haarseite des Tieres ist sehr glatt und geschmeidig. Sie ist auch als Wild- oder Vollnarbenleder bekannt. Unter dieser Deckschicht liegt ein unterschiedlich dickes Rindsleder. Wenn die Haut dick genug ist, kann sie in drei Schichten aufgeteilt werden. Daher nennt sich diese Schicht auch Spaltleder.

- Die oberste Schicht ist die beste Spaltschicht der Haut, die auch als Narbenspalt oder A-Spaltleder bekannt ist. Die Faserstruktur ist hier immer noch sehr dicht und kompakt, wodurch das Leder bei einer minimalen Reißgefahr stabil bleibt.

- Die mittlere Schicht wird als Schicht der B-Stufe oder als Kernspaltschicht bezeichnet. Diese Schicht weist eine offenere Struktur auf, obwohl sie immer noch sehr fest ist.

- Die untere Schicht der Haut wird auch als Fleischspaltschicht bezeichnet. Diese Schicht weist eine sehr grobe Faserstruktur auf, was die Gefahr von Beschädigungen und Rissen erhöht.

Typen von Tierleder

Das Leder kann von verschiedenen Tieren bezogen werden. Für die Schweißerbekleidung aus Leder wird hauptsächlich gespaltenes Rindsleder verwendet. Handschuhe können hingegen auch verschiedene andere Ledertypen enthalten. Das Kuhfell ist im Allgemeinen leichter verfügbar und ein Kuhfell hat eine größere Oberfläche als beispielsweise das Fell einer Ziege. Darüber hinaus sind Ziegen- und Hirschleder viel geschmeidiger, was für Lederhandschuhe, die zum Schweißen verwendet werden, von Vorteil ist.

- Spaltrindsleder

Das Spaltrindsleder ist aufgrund seiner Hitze- und Flammwidrigkeit ideal für die Herstellung von Schweißerkelidung und Lederhandschuhen. Dies ist auf seine hitze- und flammwiderständigen Eigenschaften zurückzuführen. Seine offene Struktur macht das Rindsleder atmungsaktiv und erhöht den Komfort. Darüber hinaus ist Rindsleder eine kostengünstige Wahl. Die Schweißerbekleidung von Lava Brown™ ist ein Paradebeispiel dafür, dass für alle Kleidungsstücke Rindsspaltleder erstklassiger Qualität (Qualitätsstufe A) verwendet wurde. Das gespaltene Rindsleder ist auch in den Arbeitshandschuhen mit einer Lederhandfläche und in mehreren Modellen der gefütterten Handschuhe von COMFOflex® zu finden.

- Narbenrindsleder

Das Narbenrindsleder eignet sich aufgrund seiner Flexibilität und Festigkeit für die Herstellung von Kleidung und Handschuhen für Schweißer. Dank seiner Wasser- und Ölbeständigkeit ist es ideal für Umgebungen mit verschiedenen Flüssigkeiten und Spritzern. Ein Beispiel für diese Art von Leder ist die Bekleidung aus genarbtem Leder von Golden Brown™. Zusätzlich wird das Narbenrindsleder auch in Schweißhandschuhen verwendet, wie zum Beispiel auf der Rückseite des Modells 10-2750 des STEERSOtuff® Schweißhandschuhs.

- Wildleder (umgekehrtes) Schweinsleder

Wildleder bzw. Schweinsleder ist von Natur aus weich und geschmeidig, so dass es sich leicht biegen lässt. Durch seine natürliche Atmungsaktivität bietet dieses Leder Komfort, ohne den Schutz zu beeinträchtigen. Das Schweinsleder hat eine angemessene Hitzebeständigkeit und Wasserabweisung, so dass es für mehrere Schweißeraufgaben geeignet ist. Der SOFTouch™ Schweißhandschuh Modell 10-1003 besteht unter anderem aus Wildleder bzw. Schweinsleder.

- Gemasertes Hirschleder

Das gemaserte Hirschleder ist aufgrund seiner bequemen Passform, Geschmeidigkeit und Wärmeisolierung ideal für die Herstellung von Schweißhandschuhen. Die Wasser- und Ölbeständigkeit tragen zur Haltbarkeit bei. Ein Beispiel für die Verwendung von Hirschleder in einem Handschuh ist der Schweißhandschuh Modell 10-2850 DEERSOsoft® mit COMFOflex®-Futter.

- Genarbtes Ziegenleder

Dieses leichte und bequeme Leder ist perfekt für Schweißhandschuhe, bei denen Geschicklichkeit unerlässlich ist. Seine Wasser- und Ölbeständigkeit erhöht die Vielseitigkeit. Der Handschuh Modell 10-1004 SOFTouch™ ist aus Ziegenleder mit Baumwollkappe gefertigt. Diese Ziegenlederhandschuhe bieten eine hohe Fingerempfindlichkeit und sind zudem sehr weich und flexibel im Gebrauch. Zusätzliche Verstärkungen machen den Handschuh weniger verschleißanfällig.

- Gemasertes Bisonleder

Das gemaserte Bisonleder bietet eine hervorragende Passform, Geschicklichkeit und Komfort. Dank seines hohen mechanischen Wertes ist dieses Leder besonders für anspruchsvolle Schweißaufgaben geeignet. Der Schweißhandbuch Modell 10-2644 SOFTouch™ aus gemasertem Bisonleder ist ideal für das Präzisionsschweißen, in dem eine extreme Fingerempfindlichkeit gefordert ist.

Eigenschaften des Leders

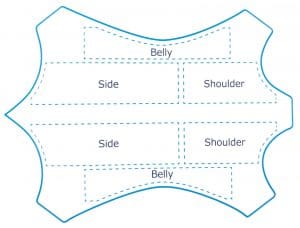

Darüber hinaus kann Leder aus verschiedenen Teilen des Tierkörpers bezogen werden. Dies wirkt sich auch auf die Lederqualität und -eigenschaften aus. Außerdem ist ein Stück Leder, das aus der Schulter entnommen, teurer als Bauchleder. Dies liegt daran, dass die Ledermenge der Schulter kleiner ist als die Menge an Leder, die aus dem Bauch entnommen werden kann. Im Folgenden listen wir die verschiedenen Teile eines Tierfells mit seinen Eigenschaften auf:

- Das Leder der Rindschulter ist bekannt für seine außergewöhnliche Geschmeidigkeit, gute Festigkeit und Flexibilität. Diese Eigenschaften machen es ideal für Produkte, bei denen Flexibilität und Komfort unerlässlich sind, wie beispielsweise für Schweißhandschuhe und -kleidung.

- Das Bauchleder gilt als die geringste Qualität, ist aber die wirtschaftlichste Wahl. Es eignet sich für Situationen, in denen die Wirtschaftlichkeit betont wird, ohne die Haltbarkeit zu sehr zu beeinträchtigen.

- Das Seitenleder hingegen bietet die beste Festigkeit und zeichnet sich durch eine konstante Qualitätsstufe aus. Dies macht es ideal für hochwertige Lederprodukte wie die Bekleidung für Schweißer, bei denen Haltbarkeit und Zuverlässigkeit von großer Bedeutung sind.

Konstante Qualität dank der eigenen Gerberei

Wir von Weldas sind der Überzeugung, dass die Sicherstellung höchster Qualität mit der Überprüfung aller Aspekte des Produktionsverfahrens beginnt. Unsere Lederprodukte sind bekannt für ihre konstante und hervorragende Qualität.

Durch die Verwendung von Wet Blue Leder, das in unserer eigenen Gerberei in Kambodscha gegerbt wird, können wir die Qualität des Leders sorgfältig überprüfen und stetig verbessern. Unsere Handwerker behandeln das Leder mit jahrelanger Erfahrung und Fachwissen hocheffizient. Dadurch erzielen wir Leder unvergleichlicher Qualität. Darüber hinaus wird das Leder einer weiteren gründlichen Qualitätskontrolle unterzogen.

Bei Weldas legen wir Wert auf Transparenz und Rückverfolgbarkeit. Daher sind alle unsere Lederbekleidungen für Schweißer und unsere Schweißerhandschuhe mit einem Produktionsetikett mit einem eindeutigen Code ausgestattet. So können wir das gesamte Produktionsverfahren von der Herkunft des Leders bis zur Gerbung in unserer Fabrik nachvollziehen.

Zertifizierung

Bei Weldas haben Qualität und Sicherheit höchste Priorität. Die Wahl der Materialien und des Designs für die Schweißhandschuhe und Schweißbekleidung sowie für andere Produkte des Weldas-Sortiments hängt demzufolge immer von der geltenden europäischen Norm ab. Deshalb werden unsere Produkte von einem Prüf- und Zertifizierungslabor geprüft und dann zertifiziert. Alle unsere Berichte und Zertifikate finden Sie auf unserer speziellen CE-Webseite. Falls Sie noch Fragen zum verwendeten Leder haben oder wissen möchten, welche Art von Leder für Ihre Schweißaufgaben am besten geeignet ist, zögern Sie bitte nicht, Kontakt mit uns aufzunehmen. Wir helfen Ihnen gerne weiter!