Why welders choose COMFOflex® welding gloves

For every professional welder, comfortable welding gloves that provide optimal hand protection are essential. Especially for MIG/MAG welders, wearing welding gloves with the highest level of protection and good lining is recommended. With COMFOflex®, Weldas offers a series of leather welding gloves that are not only highly heat-resistant and flame-retardant but also effectively absorb sweat and moisture. The COMFOflex® lining ensures maximum comfort combined with the best protection.

What is COMFOflex®?

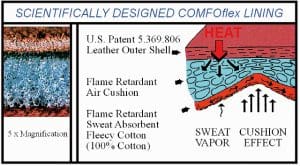

The name COMFOflex® refers to the lining developed and patented by the founder of Weldas in America. The COMFOflex® lining consists of a layer of fleece and a layer of foam. The foam serves as an air cushion, and the fleece absorbs moisture. Both materials are treated to be flame-retardant, ensuring optimal protection against heat, splashes, and sparks during welding.

Lining on the outer and/or inner side

COMFOflex® contributes to the comfort and thermal insulation of the welding glove. To provide the best protection against heat, Weldas offers models in this series of welding gloves with lining for both the palm and back of the hand. However, you can also choose a model where only the back of the leather glove has the COMFOflex® lining. This provides good heat protection on the back of the hand while simultaneously enhancing comfort and finger sensitivity.

Wide and snug-fitting welding gloves

In addition to various lining options, the COMFOflex® welding glove range includes wide and fitted models. The wide leather welding gloves can be easily removed without touching, which is particularly convenient and safe for welders working in hot welding environments or in case of emergencies. On the other hand, the fitted models provide a snug fit.

For ease of donning, Weldas COMFOflex® gloves feature a handy pull tab to ensure proper placement on the hand. This pull tab eliminates the need to tug at the glove’s cuff, thus prolonging the glove’s lifespan.

Verstevigde duim voor langere levensduur

Bij veel MIG lashandschoenen is er een extra versteviging rondom de duim geplaatst. De duim van de lashandschoen heeft vaak veel te lijden door wrijving en slijtage, omdat hiermee materialen worden vastgehouden en het laspistool bediend wordt. Door deze versterking zijn de COMFOflex® handschoenen beter bestand tegen slijtage en gaan ze ook bij intensief gebruik lang mee. Daarnaast vermindert het risico op een snijwond met een versteviging rondom de duim.

A truly heat-resistant welding glove

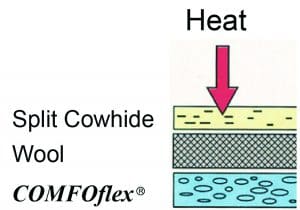

The 10-2900 COMFOflex® welding glove is designed for handling and moving hot components. It also offers good protection during cutting or close proximity to a workpiece. Made from A-grade split leather, this leather welding glove features COMFOflex® lining on both the back and palm. Between the leather and the COMFOflex® lining, there’s an additional layer of wool, providing excellent protection against extreme heat. Since this welding glove is often used in higher temperature ranges, the cuff also has a flame-retardant lining. The double lining, welting on the seams, and the use of split leather make it a bit stiffer but highly durable heat-resistant glove.

Welding gloves with heat reflection

The 10-2755 and 10-2385 gloves feature an PFR aluminum layer on the glove’s cuff. This reflects up to 95% of the arc light, reducing the impact of heat on the glove. These leather welding gloves are commonly used for higher amperage or heat-intensive welding. Beneath the rigid aluminum layer lies supple deer leather with COMFOflex® lining.

These leather gloves with heat reflection are extremely sturdy, but any damage to the aluminum layer compromises their function as a heat shield. To achieve the same effect, another welding glove can be combined with a heat shield.

Reinforced hand for extended durability

Many MIG welding gloves have extra reinforcement around the thumb area. The thumb of the welding glove often undergoes considerable friction and wear due to holding materials and operating the welding torch. With this leather reinforcement, COMFOflex® welding gloves are better equipped to withstand wear and tear even during intensive use. Additionally, it reduces the risk of cuts around the thumb area.

Stitched with KEVLAR® threads

Weldas COMFOflex® gloves are stitched with 4 and 5-thread DuPont KEVLAR® yarn for added strength. KEVLAR® yarn is not only incredibly strong, enhancing resistance to tearing and cutting, but also exhibits good heat resistance. The threads resist burning and maintain their strength and integrity even when exposed to high temperatures. These are ideal properties for use in welding gloves where protection against heat, cuts, and abrasion is crucial.

DuPont and KEVLAR® are trademarks or registered trademarks of E.I. du Pont de Nemours and Company.

Type A welding gloves – EN12477 standard

Weldas places great importance on certifying their welding clothing and gloves to meet the safety requirements for welders. Therefore, all COMFOflex® welding gloves are Type A certified according to the European EN12477 standard. This standard specifies the minimum requirements for leather welding gloves used in welding and related processes.

This certification ensures that the gloves meet the minimum requirements for protection against thermal hazards such as heat, splashes of molten metal, and flames. Additionally, the gloves must be sufficiently durable while also providing adequate comfort and flexibility to perform welding tasks. Leather welding gloves undergo rigorous testing procedures before certification.

Choose the Weldas welding glove that suits you

Browse the range of COMFOflex® welding gloves from Weldas and determine which model and size of welding glove best suit your needs based on all product specifications, qualifications, and certifications. For additional product information or expert advice, feel free to contact us.